Blast cleaning is a highly efficient and versatile method for cleaning and preparing metal surfaces. It involves using abrasive materials propelled at high speeds to remove unwanted substances from the surface. Blast cleaning can eliminate rust, scale, paint, coatings, dirt, and other contaminants, leaving behind a clean and smooth surface that is ready for further treatment or use.

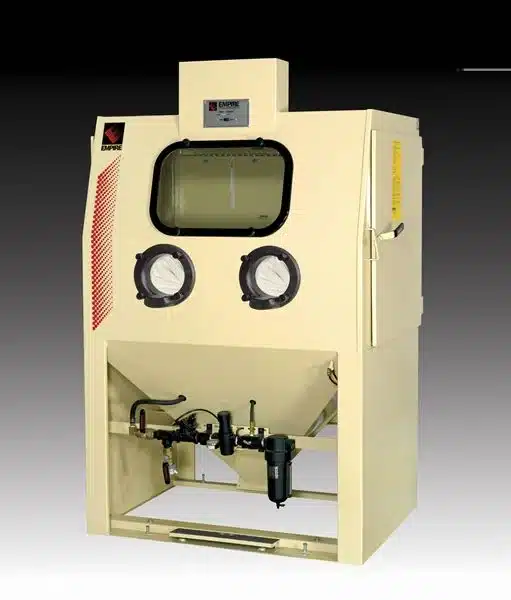

Abrasive blasting is the most common form of blast cleaning. It utilizes abrasive materials, such as sand, steel shot, glass beads, or aluminum oxide, to remove surface contaminants. The abrasive material is propelled by compressed air or water pressure, creating a force that effectively cleans and prepares the surface.

Shot blasting is a variant of abrasive blasting involving steel shots or pellets as the abrasive material. These shots are propelled at high velocities, impacting the surface and removing contaminants. Shot blasting is particularly effective in cleaning and preparing metal surfaces for subsequent treatments or coatings.

Blast cleaning effectively removes various contaminants from metal surfaces. Rust, scale, paint, coatings, dirt, and other unwanted substances can be stripped away, revealing a clean and bare surface. This removal of contaminants improves the appearance of the metal and prepares it for subsequent treatments or coatings.

Blast cleaning is an excellent method for surface preparation. By removing contaminants and creating a clean and roughened surface, blast cleaning enhances the adhesion of subsequent coatings or treatments. This ensures a stronger bond between the surface and the protective or decorative layer, improving longevity and performance.

Blast cleaning can restore metal surfaces to their original state. By removing corrosion, old coatings, and other imperfections, blast cleaning reveals the true beauty and quality of the metal. This is particularly beneficial for historical or antique metal pieces that require careful cleaning and preservation.

Steel and iron surfaces often require blast cleaning to remove rust, scale, and old coatings. Blast cleaning restores their appearance and prepares them for further treatments or coatings. Blast cleaning services can benefit steel structures, machinery, automotive components, and ironworks.