Normalizing can significantly improve the material’s strength, toughness, and uniformity with its controlled heating and cooling, resulting in superior performance.

It is a heat treatment process used to refine the microstructure of metal components. It involves heating the material above its critical transformation temperature and controlled cooling in still air.

Normalizing helps to achieve a uniform and fine-grained microstructure throughout the material, improving its mechanical properties.

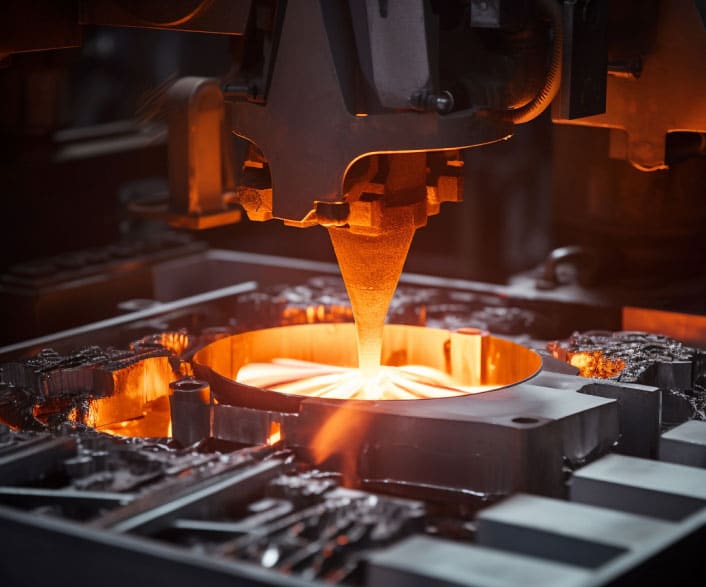

The normalizing process begins with heating the metal component to a temperature above its upper critical point. This allows the material’s microstructure to transform into austenite, a non-magnetic phase with high-temperature stability.

After reaching the desired temperature, the component is held at that temperature for a specified period. This soaking time allows for the complete transformation of the microstructure and the dissolution of any remaining precipitates.

Following the soaking period, the component is cooled in still air. The controlled cooling rate during normalizing is slower than that of quenching, allowing the formation of a more refined and uniform microstructure.